The

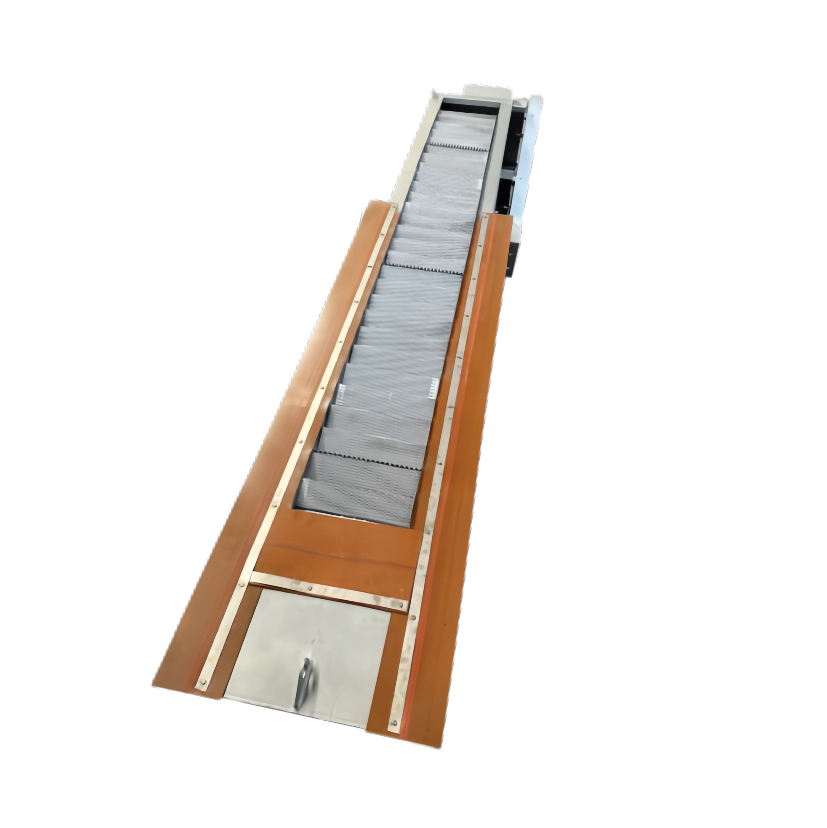

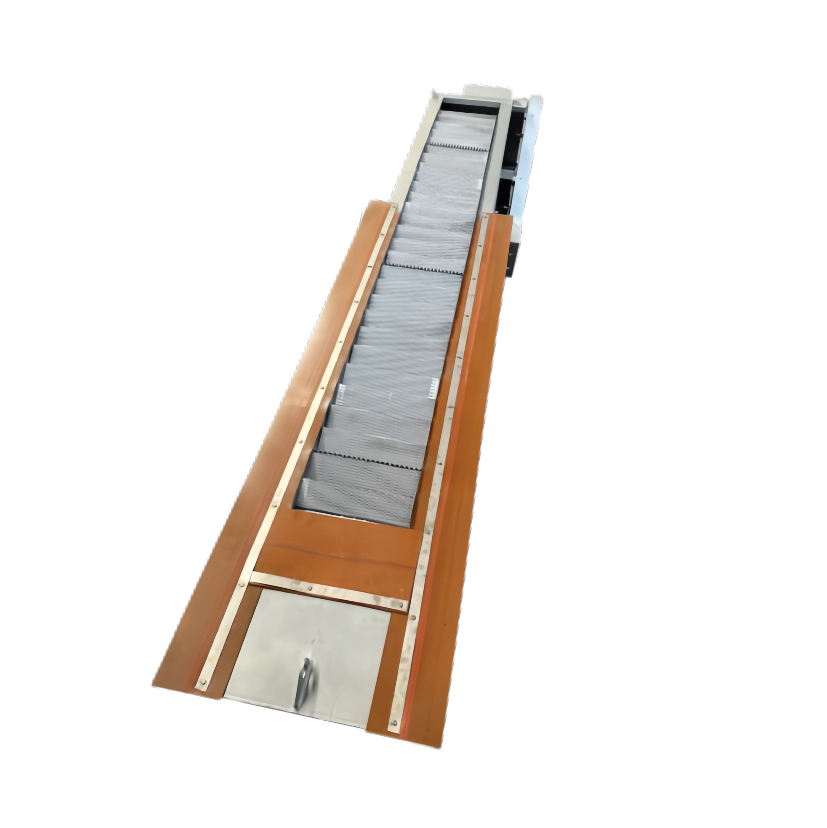

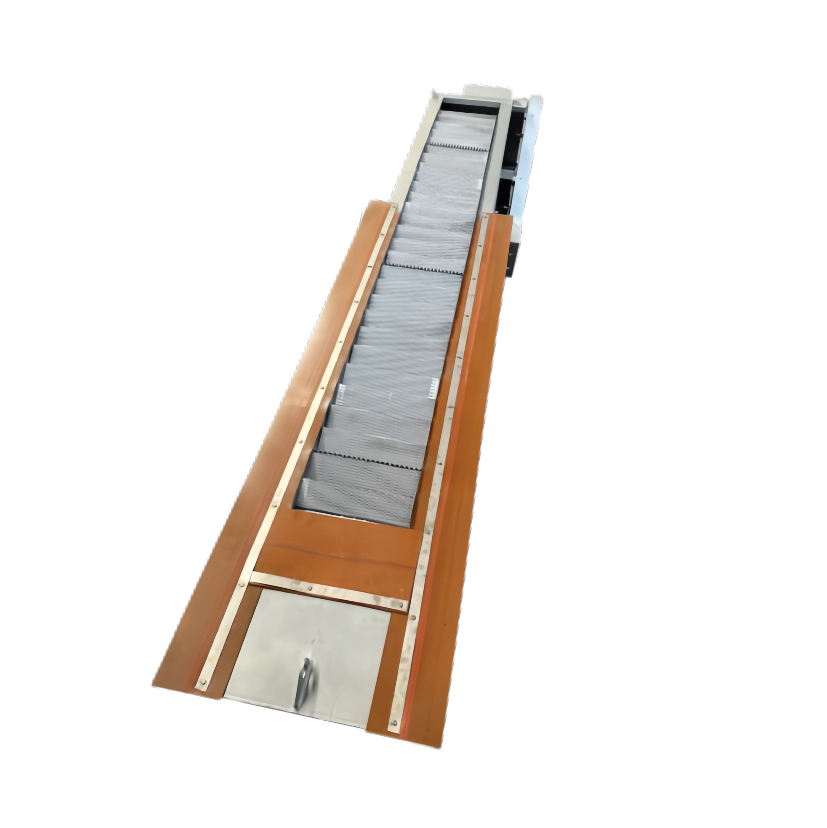

Grille Decontamination Machine is introduced as a

Solid-liquid Separation mechanical device that removes debris (generally called dirt) attached to the pollution grill. In reservoirs or rivers with a lot of dirt, in order to ensure safe and normal operation of hydropower stations or pumping stations, it is often necessary to set up a dirt cleaning machine to clean dirt without shutting down or emptying the reservoir.

The Grille Decontamination Machine consists of a unique rake tooth factory assembled into a set of rotary grille chains. Driven by the motor reducer, the rake tooth chain rotates against the direction of the water flow.

When the rake tooth chain moves to the upper part of the equipment, due to the guidance of the sheaves and curved rails, a relative self-cleaning movement occurs between each set of rake teeth, and most of the solid materials fall down by gravity. The other part relies on the reverse movement of the cleaner to clean the debris stuck on the rake teeth.

The rake tooth chain is similar to the grid according to the direction of water flow. The rake tooth gap assembled on the rake tooth chain shaft can be selected according to the use conditions. When the rake teeth separate the solid suspended solids in the fluid, they can ensure the smooth flow of water. The entire working process of

Wastewater Treatment is continuous or intermittent.

The biggest advantages of this equipment are high degree of automation, high separation efficiency, low power consumption, no noise, and good corrosion resistance. It can ensure continuous and stable operation when left unattended. It is equipped with an overload safety protection device to prevent equipment failure in the event of equipment failure. When the machine is running, it will automatically shut down to avoid overloading the equipment. This equipment can arbitrarily adjust the operation interval of the equipment according to the user's needs to achieve periodic operation; it can be automatically controlled according to the liquid level difference before and after the grille; and it has a manual control function to facilitate maintenance. Users can choose any one according to different work needs.

Due to the reasonable structural design of the equipment, it has a strong self-purification ability when the equipment is working, and will not cause clogging, so the daily maintenance workload is very small.