Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

| Model |

$210-672 /Piece/Pieces

| Selling Units: | Piece/Pieces |

|---|

Structural features

1. Using advanced Australian technology, the appearance is beautiful and elegant.

2. High structural rigidity, smooth operation and low noise.

3. Equipped with advanced concentration pretreatment equipment (good for sludge flocculation) and low operating cost.

4. The gravity dewatering area is equipped with advanced distributors to distribute materials evenly and extend the life of the filter belt.

5. It has an extra-long gravity dewatering zone and a wedge-shaped dewatering zone, which fully dehydrates the material and ensures that the material will not overflow in the pressing zone.

6. The roller system is arranged scientifically and orderly. Gravity dehydration, wedge dehydration and press dehydration are discharged separately without interfering with each other. The diameter ratio of the press dehydration roller is large and the dehydration effect is good. Therefore, it has large production capacity, energy saving and high efficiency.

7. The continuous operation from feeding to mud cake discharge has a high degree of automation. A PLC interface can be set up as needed to facilitate centralized microcomputer control.

8. The power transmission mechanism adopts mechanical or variable frequency stepless speed regulation, with a large speed regulation range and wide adaptability.

9. The filter belt is equipped with a reliable backwash device to ensure the dehydration effect of the filter belt.

10. Use pneumatic tensioning and pneumatic automatic deviation correction devices to ensure the safe and normal operation of the filter belt.

11. The operation is safe and reliable, using infrared safety protection and a full range of emergency safety parking devices.

12. Filter belts with different structures can be configured according to different materials to achieve high filtration accuracy.

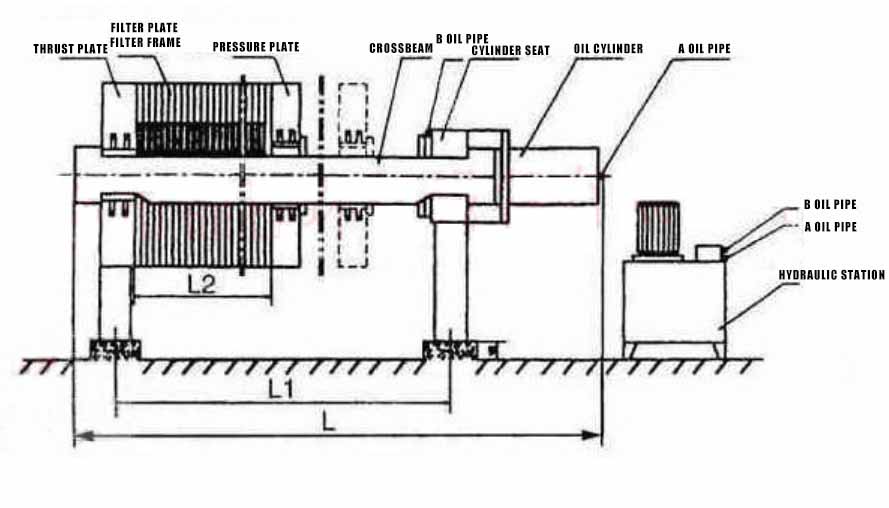

The hydraulic pressing mechanism of the filter press consists of a hydraulic station, a cylinder, a piston, a piston rod, and a Hafland card hydraulic station that connects the piston rod and the pressing plate. The structure of the hydraulic station consists of a motor, an oil pump, and a relief valve (for regulating pressure). Directional valve, pressure gauge, oil line, oil tank.

Filtration method: The way the filtrate flows out is divided into open flow filtration and undercurrent filtration. For open-flow filtration, the outlet hole at the bottom of each filter plate is equipped with a water nozzle, and the filtrate flows out of the water nozzle intuitively. In underflow filtration, there is a liquid outlet hole under each filter plate. The liquid outlet holes of several filter plates are connected to form a liquid outlet channel, which is discharged through a pipe connected to the liquid outlet holes under the thrust plate.

Washing method: When the filter cake needs to be washed, sometimes there is one-way washing and two-way washing, and undercurrent one-way washing and two-way washing.

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.