filter mechanism

The filter mechanism consists of a filter plate, a filter frame, a filter cloth, and a press diaphragm. Both sides of the filter plate are covered by filter cloth. When a press diaphragm is required, a set of filter plates consists of a diaphragm plate and side plates. The base plate of the diaphragm plate is covered with rubber diaphragms on both sides, and the outside of the diaphragm is covered with filter cloth. The side plates are ordinary filter plates. The material enters each filter chamber from the material hole on the thrust plate. The solid particles are trapped in the filter chamber because their particle size is larger than the pore size of the filter medium (filter cloth). The filtrate flows out from the outlet hole below the filter plate. When the filter cake needs to be squeezed dry, in addition to squeezing with a diaphragm, compressed air or steam can also be passed through the washing port, and the air flow can wash away the water in the filter cake to reduce the moisture content of the filter cake.

(1)Filtering method

The way the filtrate flows out is divided into clear flow filtration and undercurrent filtration.

A. Open flow filtration: The outlet hole at the bottom of each filter plate is equipped with a water nozzle, and the filtrate flows out of the water nozzle intuitively.

B. Undercurrent filtration: There is a liquid outlet hole under each filter plate, and the liquid outlet holes of several filter plates are connected to form a liquid outlet channel.

channel, discharged from the pipe connected to the liquid outlet hole under the thrust plate.

(2)Washing method

When the filter cake needs to be washed, there are open flow one-way washing and two-way washing, and undercurrent one-way washing and two-way washing.

A. Open flow one-way washing means that the lotion enters sequentially from the lotion inlet hole of the thrust plate, passes through the filter cloth and then through the filter cake, and flows out from the non-porous filter plate. At this time, the liquid outlet nozzle of the perforated plate is closed. status, the liquid outlet nozzle of the non-orifice plate is open.

B. Open flow two-way washing means that the washing liquid is washed twice from the washing liquid inlet holes on both sides above the thrust plate, that is, the washing liquid is washed from one side first and then from the other side. The outlet of the washing liquid is opposite to the inlet. Diagonal direction, so it is also called two-way cross washing.

C. Undercurrent unidirectional flow washing means that the washing liquid enters the perforated plate from the washing liquid inlet hole of the thrust plate, passes through the filter cloth and then through the filter cake, and flows out from the non-porous filter plate.

D. Undercurrent two-way washing means that the lotion is washed twice successively from the two liquid inlet holes on both sides above the stop plate, that is, washing is done from one side first and then from the other side. The outlet of the lotion is diagonal. direction, so it is also called undercurrent two-way cross-washing.

(3) Filter cloth: Filter cloth is a main filter medium. The selection and use of filter cloth play a decisive role in the filtration effect. When selecting, appropriate filter cloth should be selected based on the PH value of the filter material, solid particle size and other factors. The material and pore size are selected to ensure low filtration cost and high filtration efficiency. When using, make sure the filter cloth is flat and undistorted and the pore size is unobstructed.

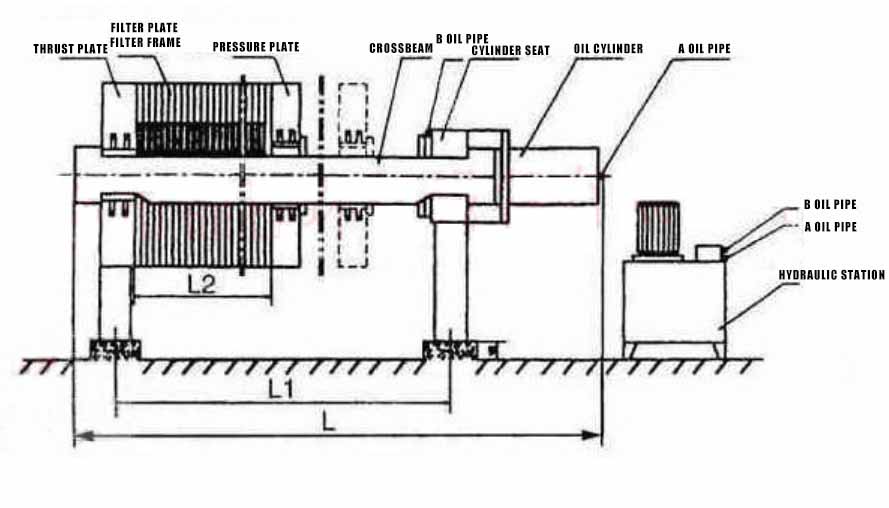

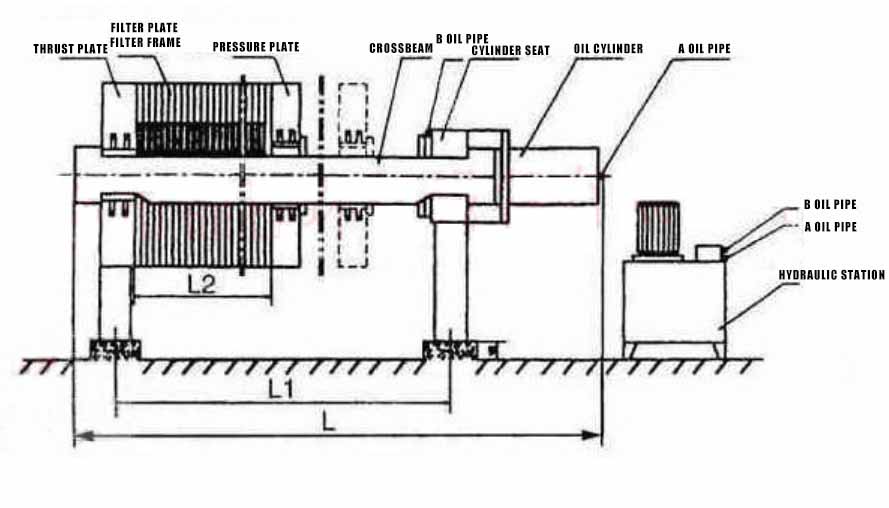

The hydraulic pressing mechanism of the Filter Press consists of a hydraulic station, a cylinder, a piston, a piston rod, and a Hafland card hydraulic station that connects the piston rod and the pressing plate. The structure of the hydraulic station consists of a motor, an oil pump, and a relief valve (for regulating pressure). Directional valve, pressure gauge, oil line, oil tank.

Filtration method: The way the filtrate flows out is divided into open flow filtration and undercurrent filtration. For open-flow filtration, the outlet hole at the bottom of each filter plate is equipped with a water nozzle, and the filtrate flows out of the water nozzle intuitively. In underflow filtration, there is a liquid outlet hole under each filter plate. The liquid outlet holes of several filter plates are connected to form a liquid outlet channel, which is discharged through a pipe connected to the liquid outlet holes under the thrust plate.

Washing method: When the filter cake needs to be washed, sometimes one-way washing and two-way washing, undercurrent one-way washing and two-way washing