Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

| Model |

$1039-5999 /Piece/Pieces

| Selling Units: | Piece/Pieces |

|---|

The operation process of the filter press in sludge water treatment mainly includes five steps: feed filtration, secondary pressing, air blowing, cake unloading, and filter cloth washing.

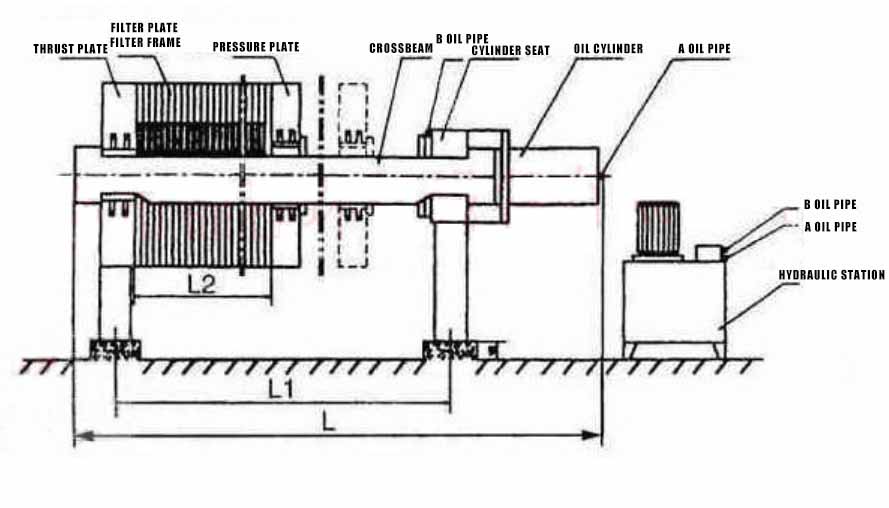

When the "Material Crossing the Shore" step is started, the piston rod of the liquid cylinder and the pressing plate move the Filter Plate towards the thrust plate and press it tightly, forming a series of sealed filter chambers between the filter plates. The PAM distribution system is running, and in front of the feed pump Note

medicine, the feed pump starts, and the mud is sent into each flow chamber through the center hole of the thrust plate. With the pressure of the feed pump, the mud passes through the back of the filter cloth and enters the drainage ditch and drainage hole drainage system on the filter plate, and the solid matter is trapped A mud cake gradually forms in the filter cavity.

The "feeding and filtering" step ends, the injection of medicine is stopped, and the "secondary pressing" step is entered. The filter plate diaphragm expands and squeezes to dehydrate the mud cake for the second time. The "secondary pressing" is completed and the "air blowing" step is entered. Leli air is introduced into the filter cavity through the drainage channel in the upper right corner of the filter plate and discharged through the drainage hole at the bottom of the plate, taking away some free water on the surface of the filter cake. The "secondary blowing" step ends and enters the "sludge unloading" step. The piston rod of the hydraulic cylinder drives the pressing plate to move back to release the filter plate. The manipulator pulls the filter plate piece by piece to unload the cake. After the cake unloading is completed, flushing is started depending on the situation. filter cloth program or enter the second filter press operation cycle.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.