Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

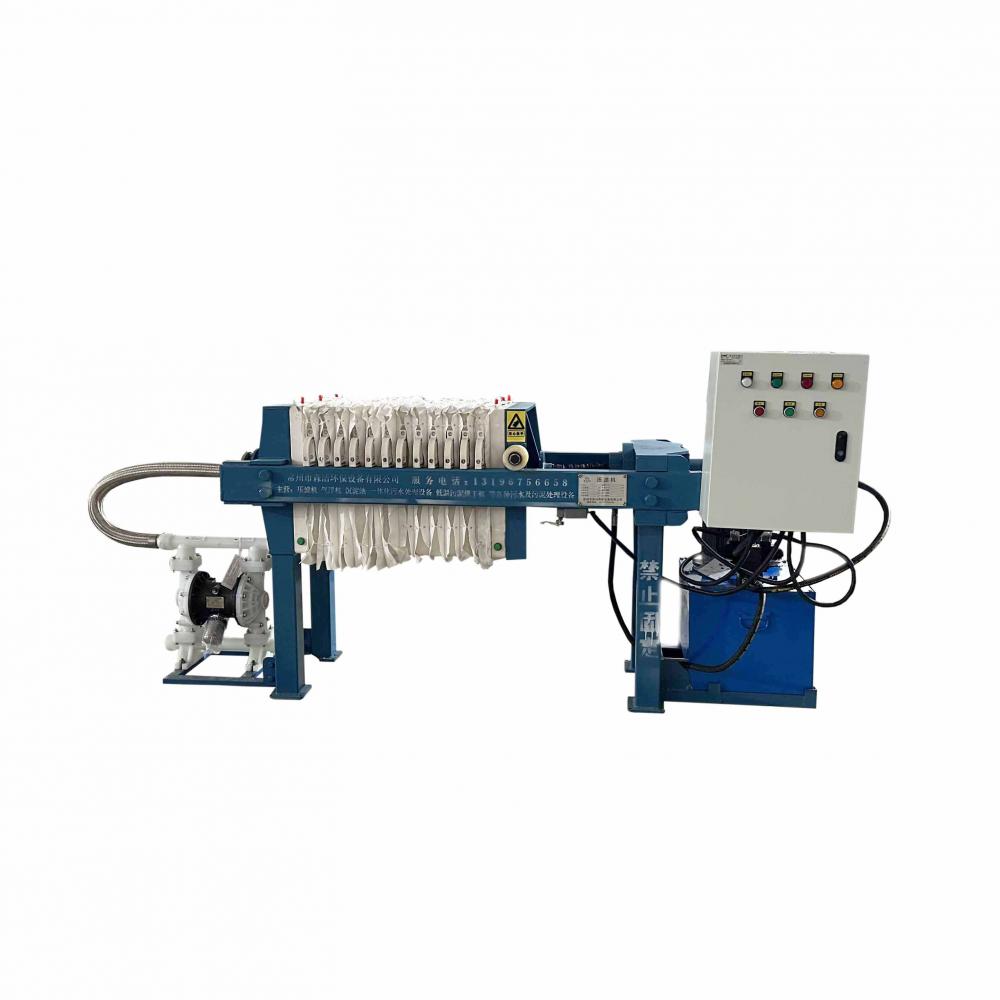

$359-879 /Piece/Pieces

| Selling Units: | Piece/Pieces |

|---|

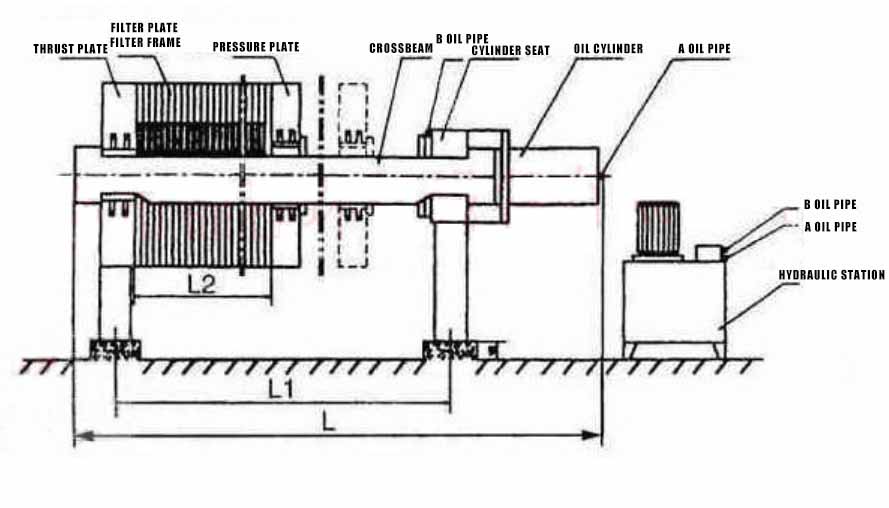

The plate and frame filter press consists of a filter plate and a hollow filter frame. The filter cloth is fixed on the filter plate. The main advantage is that it is easy to replace the filter cloth. The disadvantages are low efficiency, low filtration pressure, and large filter chamber. It is easy to form a bias voltage and cause damage to the filter plate. The plate and frame filter press is mainly suitable for materials whose filtration concentration is not high and requires filter paper for fine filtration. It is not recommended to use plate and frame filter presses for general sewage treatment, coal preparation, non-ferrous metal mineral processing, etc., but a chamber filter press should be used.

The chamber filter press is a plate and frame filter press. In recent years, its frequency of use is higher than that of the plate and frame filter press. The single-layer filter plate of the chamber filter press is thicker than the plate and frame filter plate. In other words, the box filter is composed of two identical filter plates. When the two filter plates are pressed together, a filter chamber is formed. Suitable for storing granular objects separated by filter cloth. The feed hole is located in the center of the filter plate. Generally used for materials containing a large amount of granular objects, such as sewage treatment, mineral processing, coal washing and other industries. Chamber filters should not cause damage to each filter chamber. Bias pressure prevents the filter plate from being damaged, the filtration speed is fast, the residue is easy to be unloaded, the filtration pressure is high, the liquid content of the filter cake is low, and the filter cake can withstand filtration pressures up to 6.0 Mpa. It has wider adaptability and can manufacture large filters.

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.